Knick Ceramat

Built for the Extreme, Engineered for Reliability

Ceramat: The Ultimate Solution

Ceramat retractable fittings are ideal for extreme applications involving corrosive, hot, toxic, or high-pressure media. Featuring a unique ceramic sealing system with superpolished planar disks, they offer superior durability and resistance to chemical, thermal, and mechanical stresses. These fittings enable adjustment, cleaning, and sensor replacement without process interruption, ensuring maximum availability and safety. Proven in demanding conditions, Ceramat fittings provide reliable and robust solutions for continuous and safe operations.

Ceramat Overview |

|||

|

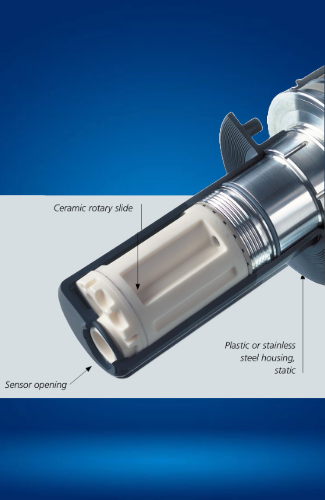

This patented retractable fitting with a ceramic sealing system is designed to handle challenging applications where conventional O-ring seals fail. The unique lock-gate principle uses two planar ceramic disks that rotate towards each other, effectively separating the calibration chamber from the process. This ceramic seal is harder than steel and highly resistant to chemical, thermal, and mechanical influences, ensuring maximum availability and process safety. |

|||

Key Features:Maximum Process Safety:

Maintenance Without Process Interruption:

Versatile Applications:

|

|

||

Key Facts:Maximum Availability:

Versatile Process Adaptations:

Plug & Play:

Cyclone Rinsing:

Ceramic Sealing Advantages:

Easy Drive Replacement:

|

|

||

Download PDF: Knick Ceramat Product Brochure PDF

Ceramat Product Range

Ceramat WA 150 / WA 153

The Ceramat WA 150 / WA 153 retractable fitting features a pneumatic sensor lock-gate with application-specific process adaptation. It is available in carbon-fibre-reinforced PVDF and PEEK (WA 150), as well as stainless steel, titanium, and Hastelloy (WA 153).

Key Facts:

- Virtually wear-resistant

- Sterilizable

- Plug & Play with central multiplug

- Easy maintenance under process conditions

- Cyclone rinsing for optimal cleaning

- Superior sensor immersion depth

- Standard sensor length of 225 mm

- Designed for challenging process conditions and applications

Applications:

- Highly corrosive processes (chlorine production, phosgenation)

- Processes with depositing, abrasive, and incrusting solids

- Flue gas desulphurisation

- Gas scrubbers

- Sugar production

- Dyes and pigment synthesis

- Special incrusting industrial wastewaters

Download PDF: Ceramat WA 150 Datasheet

Download PDF: Ceramat WA 153

Ceramat WA 154 - CeraLong

The Ceramat WA 154 combines proven Ceramat functionality with an extended immersion depth of up to 300 mm. This retractable fitting features a robust housing made of stainless steel, Hastelloy, or titanium, along with a ceramic lock-gate sealing system.

Key Facts:

- Gaskets replaceable during the running process

- Compatible with DN 50 and 2″ or larger ANSI flanges

- Torsion protection for fibre-optic sensors

- Pressure-resistant up to 10 bar at 140 °C

- Safety pressure up to 40 bar at 140 °C

- Ceramically sealed fitting for electrochemical sensors (12 mm diameter) or optical sensors (12 mm or 12.7 mm diameter)

- Available in titanium and Hastelloy

Applications:

- Suitable for processes requiring robust sealing and high durability

- Ideal for environments with high pressure and temperature conditions

- Used in various industrial settings needing extended sensor immersion depth and reliable sealing

Download PDF: WA 154 CeraLong Datasheet

Ceramat WA 160

The Ceramat WA 160 is a fully automatic retractable fitting designed for high immersion depths, reaching up to 2000 mm. It is ideal for use in tanks, basins, and conduits, supporting electrochemical sensors with diameters of 12 mm.

Key Facts:

- Immersion depths range from 600 to 2000 mm

- Immersion tube diameter is only 65 mm

- Simple sensor replacement, even for 2000 mm immersion depth

- Compatible with sensors that are 225 mm long with solid electrolyte (gel, paste, polymer, etc.)

- Features 2 independent barriers with cavity rinsing

Applications:

- Highly Corrosive Processes: Chlorine production, phosgenation

- Processes with Depositing, Abrasive, and Incrusting Solids: Flue gas desulphurisation, gas scrubbers, sugar production (1st and 2nd carbonatation), dyes and pigment synthesis, special crust-forming industrial wastewater

- Pulpy, Fibrous Media: Cellulose, cosmetics, food

- Organic and Sticky Residues: Refinery wash water, starch production

- Highly Toxic Substances: Processes involving phosgene gas and hydrogen cyanide

Download PDF: Ceramat WA 160 Datasheet

Download PDF: Ceramat Accessories Datasheet

Supplied by DP-Flow

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222