Dual Chamber Fitting

The EMCO dual chamber orifice fitting is designed and constructed to allow for the orifice plate replacement or inspection under pressure without the interruption of the flow in the pipe line.

The EMCO type EDC orifice fitting is a high quality, high accuracy orifice fitting manufactured in a wide selection of sizes and materials.

Principle

EMCO type EDC pressurized dual chamber orifice fitting also known as senior orifice fitting is used as a primary element in flow measurement according to the differential pressure principle. The EMCO type EDC measures the flow of most liquids and gases within the process industries, including off shore, oil and gas, petro-chemical. The EMCO type EDC orifice fitting is based on the principle of measuring velocity in the pipe line, therefore the flow measurement is volumetric. The dual chamber orifice fitting flow meters are backed by international standards covering flow calculation, manufacturing tolerances, accuracy and installation requirements.

Features

The EMCO type EDC orifice fitting is a high quality, high accuracy orifice fitting manufactured in a wide selection of sizes and materials. These units are built to meet or exceed ASME and ANSI specifications as well as to comply with the requirements of the latest editions of ISO-5167, AGA-3, and API-14.3.

The fittings are available to meet the NACE MR-01-75 specification.

Accessories

Complete custom-built meter runs with flange and/or weld ends and flow conditioners. Secondary instrumentation including static pressure transmitter, differential pressure transmitter, temperature sensor and temperature transmitter with thermowell, valves, instrument tubes and fittings, flow computer.

Certification

- Material certificate according to EN 10204-3.1, hydraulic pressure test, NDT of weldings if applicable, dimensional test, 3rd party inspection.

- CE marking.

- Documentation

- Bore calculation, dimensional drawing

- Technical data

- Design and calculation standards : ISO 5167, ASME MFC-3M, AGA no. 3, ASME/ANSI B 16.5, ASME B 16.34

- Sizes : 2" to 26" - 150 to 600 lbs; 2" to 16" - 150 to 1500 lbs

- Body materials : SA216 WCB, SA352 LCC or A351 CF8M

- Internal Parts : AISI 4130 Carbon Steel, 316 or A351 CF8M Stainless Steel

- Process connection : Flange/flange, welding neck/flange, welding neck/welding neck

- Flange facing : Raised face RF or ring type joint RTJ

- Pipe schedules : 40, 60, 80, 100, 120, 160 or to customer´s specification

- Sealings : Body and seal bar: Nitrile O-Ring Standard, optional Teflon. grease, Seal Standard Nitrile O-Ring

- Orifice Plate Seals: Formed Nitrile Seals Standard, Dual Ring Assembly: Nitrile O-ring Standard, Snap Seal: Teflon,

- Tap Connections : Two ½" NPT per side standard, two ½ NPT additional per side optional (TT)

- Orifice Plate Seal Gap : 2" - 6" = 14,27 mm, 8" - 14" = 17,48 mm, 16" - 20" = 20,65 mm, 24" and above = 22,23 mm

- Operating shaft location: Standard on left hand side on fitting sizes up to and including 16", Dual operation on 20" and above

- Operating temperature : Standard at -30 to +60 °C, optional -40 to +120 °C

- Operating Position : Vertical or horizontal

Seal Construction

1. Type "K" Standard seal assembly

This is the standard seal assembly supplied with all orifice fittings from sizes 2" through 8". This unit is used with a 14,27 mm seal gap for fitting sizes 2" to 6" and with a 17,48 mm seal gap for 8" fittings. The single downstream seal function offers superior sealing capability while reducing seal damage during insertion.

Plate seal bypass tested down to 25 mm water column. It is comprised of an elastomer seal and one stainless steel retainer ring.

Exacting and repeatable concentricity is maintained with the metal-to-metal contact throughout the entire circumference of the orifice plate to the plate carrier mechanism.

2. Teflon snap seal

The Teflon snap seal provides positive plate sealing in the harshest of process environments. The two piece design snaps over the orifice plate without the use of metal clips or retainers. A specially designed recess absorbs the insertion pressures minimizing permanent compression and distortion.

The raised section adjacent to the recess creates a positive seal against the orifice plate preventing bypass leakage. These two unique design features enhance seal performance while extending the life expectancy of the seal assembly.

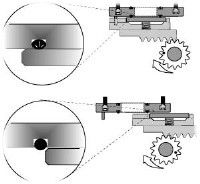

Soft Seat Details

This unique soft seat design is available at no extra charge. It enables a maintenance free bubble tight seal between upper and lower chambers. Standard size O-Ring seals are incorporated and available in a wide variety of compositions.

Order Coding

- 1. Nominal size

- 2, 3, 4, 6, 8, 10, 12, 14, 16, 20, 24, 26

- 2. ANSI Rating

- 15 - 150, 30 - 300, 60 — 600, 90 - 900, 150 - 1500

- 3. Flange Facing

- RF - Raised Face; RJ - Ring Type Joint; NF - No Flange

- 4. Model

- EDC - Dual Chamber

ESC - Single Chamber - 5. Pipe schedule

- 30, 40, 60, 80, 100, 120, 160, XXX

- 6. Trim

- S — Standard

SS - Corrosive 316 SS - 7. Valve Seat type

- A - Grease

B - Soft Seal,

(Leave Blank on Model ESC) - 8.Body Material Specification

- W - A216 WCB

L - A352 LCC - 9. End connection

- FF - Flanged both ends

WF - Butt weld up s, flange down s

WW - Butt weld both ends - 10. Specification

- 5167 - ISO-5167

00 — AGA-3, 4th edition - 11. Instrument Taps

- Blank - One set of taps per side

TT-Telemetering - Extra set per side

SS - A351 CF8M Stainless

Example

6", 300 lbs, RF, Dual Chamber, schedule 40, standard trim, grease valve seal, carbon steel A216WCB, plate calculation to ISO 5167, flanged connection, 1 set of tappings on each side

has the following code: 6-30-RF-EDC-40-S-A-W-5167-FF-

Works with:-

Differential pressure transmitters:-IDP10; IDP15; IDP25; IDP31; IDP50

And all our Absolute Pressure and Gauge Pressure transmitters, Temperature sensors and mass flow computers.

MultiVariable Transmitters :- IMV25, IMV30

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222

Supplied by DP-Flow