Orifice Plate MES

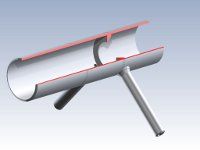

Orifice Plate with Single Pressure Tapping Series in all Welded Construction MES

EMCO orifice plates are used as primary elements in flow measurement of steam, liquid, and gas according to the differential pressure principle.

Design and calculation standards :

- ISO 5167-2, ASME MFC-3M, DIN 19215, Shell Flow Meter Engineering Handbook, AGA no. 3

- Sizes : DN 50 - 1000 according to DIN 2402

- Pressure rating : PN 10 - 400, 150 - 2500 lbs

- Plate thickness : 10 mm

- Vent or drain hole : On request

- Material : Carbon steel P235GH, AISI 316, 16Mo3, 13CrMo4-5, 10CrMo9-10, WB 36, X20CrMoV121, other materials on request

- Mounting style : Weld ends according to DIN 2559 or ANSI B16.25

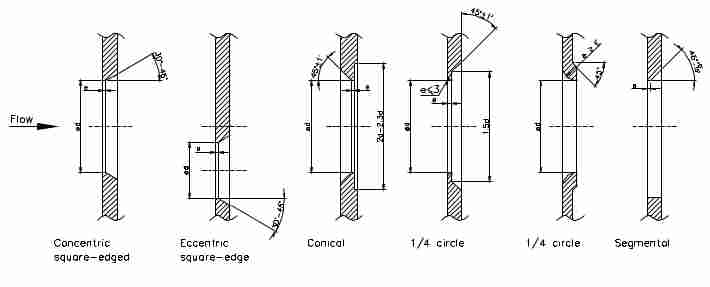

- Orifice plate shapes : Square edge concentric, square edge eccentric, conical, 1/4 circle, segment. The plate is bevelled on the down stream side except for 1/4 circle orifice plate.

- Pressure taps : Ø 21.3 mm, 24 mm, 26.9 mm, 1⁄2" BSP male, 1⁄2" NPT male

- Tap lengths : 150 mm, others on request.

- Tap location : Tap location for steam flow: 180°. At least 45° apart for liquid and gas. To be stated with order

- Marking : The orifice plate is marked with "+" and "-" and flow direction.

- Accessories : single and double shut-off valves and condensing chambers for steam flow measurement

- Technical Data

- Accuracy : +/- 0,5 % for β < 0,6 and equal to β for β values above 0,6

- Pressure loss : Depending on β, for β equal to 0,6 : ca. 60 % of the differential pressure measured

- Limits for Reynolds No : Re > 1260 x β2 D according to ISO 5167, 2000 < Re < 108 according to ASME MFC-3M?

Dimensions

All dimensions in mm

| DN | Ø Inner pipe | Upstream length | Total length | Upstream length | Total length |

|---|---|---|---|---|---|

| ISO 5167 | ISO 5167 | DIN 19215 | DIN 19215 | ||

| 50 | 45 - 57 | 115 | 230 | 150 | 250 |

| 65 | 58 - 72 | 145 | 290 | 180 | 300 |

| 80 | 73 - 90 | 180 | 360 | 230 | 350 |

| 100 | 91 - 112 | 225 | 450 | 280 | 400 |

| 125 | 113 - 137 | 275 | 550 | 350 | 500 |

| 150 | 138 - 162 | 325 | 650 | 400 | 600 |

| (175) | 163- 187 | 375 | 750 | 470 | 700 |

| 200 | 188 - 225 | 450 | 900 | 570 | 800 |

| 250 | 226 - 275 | 550 | 1100 | 690 | 1000 |

| 300 | 276 - 325 | 650 | 1300 | 820 | 1200 |

| 350 | 326 - 375 | 750 | 1500 | 950 | 1400 |

| 400 | 376 - 425 | 850 | 1700 | 1050 | 1500 |

| 450 | 426 - 475 | 950 | 1900 | 1200 | 1700 |

| 500 | 476 - 550 | 1100 | 2200 | 1370 | 2000 |

| 600 | 551 - 650 | 1300 | 2600 | 1500 | 2000 |

| 700 | 651 - 750 | 1500 | 3000 | 1500 | 2000 |

| 800 | 751 - 850 | 1700 | 3400 | 1500 | 2000 |

| 900 | 851 - 950 | 1900 | 3800 | 1500 | 2000 |

| 1000 | 951 - 1100 | 2200 | 4400 | 1500 | 2000 |

Works with:-

Differential pressure transmitters:-IDP10; IDP15; IDP25; IDP31; IDP50

And all our Absolute Pressure and Gauge Pressure transmitters, Temperature sensors and mass flow computers.

MultiVariable Transmitters :- IMV25, IMV30

Download Manual (Not Available)

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222

Supplied by DP-Flow