40P Flow

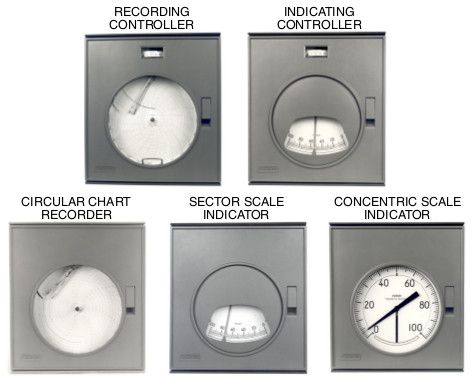

Flow recorders indicators and controllers 40P

The Model 40P Flow Recorders, Indicators, and Controllers use the dependable Type 37 Diaphragm Measuring Element as the differential pressure sensor. This accurate and time-proven combination continuously records, indicates, or controls flow rate (differential pressure is proportional to the square of the flow rate) in conjunction with primary devices such as orifice plates, flow nozzles, or Venturi Tubes. These instruments can also be used to measure differential liquid levels, or other differences in pressure

MANY APPLICATIONS - HIGH PERFORMANCE

These instruments are used in a variety of liquid, gas, and vapor flow applications, and liquid level head applications. They are particularly suited for wet gas flow measurement because of a self-draining feature. Because no mercury is used in the element, there is no need for precise leveling. These mercuryless flowmeters have an inherent stability and excellent

accuracy.

WIDE SELECTION OF CALIBRATION RANGES

Differential pressure (ΔP) calibration ranges are available between 0 to 5 and 0 to 50 kPa, 0 to 20 and 0 to 200 inH2O, and 0 to 50 and 0 to 500 mbar. Zero differential pressure can be elevated (compound range) so that the lower range value is as low as minus 50% of span; or suppressed so that the upper range value is as high as either 150% of span, or 50 kPa (200 inH2O, 500 mbar), whichever is less.

CHOISE OF CONTROL MODES

On-off, proportional, proportional plus derivative, proportional plus integral (reset), proportional plus integral plus derivative, and narrow band proportional actions are available.

DURRABLE, WEATHERPROOF CONSTRUCTION

A glass fiber reinforced case and gasketed door, with a shatterproof glass window, provide exceptional protection against many hostile environments. This construction provides the environmental protection of IEC IP53 and the raintight protection of NEMA Type 3.

OVERRANGE PROTECTION

Overrange to 14 MPa (2000 psi, 140 bar or kg/cm2) does not damage the differential pressure element, nor significantly affect calibration. This is because the diaphragms are equipped with spacer rings which are welded to the inner fold of each diaphragm section. These rings provide positive, solid stops if the element is subjected to overrange.

PRECISION MOTION TRANSFER

Smooth, low friction motion is transferred from the diaphragm by a simple drive bar pivoted on flexure strips of cobalt-nickel metal alloy. The drive bar is linked to the base instrument mechanism to provide a crisp, direct, linear transmission of differential pressure changes. A micrometer adjustment on the pen or pointer arm enables precise zero setting.

EXTERNAL DAMPING

Damping occurs when the area of the passage between the two diaphragms is restricted. This is conveniently accomplished by turning the damping screw adjustment located externally, at the top of the element. The damper is adjustable while the instrument is in service and under pressure. It provides accurate control of instrument response, yet cannot damp out the measurement completely.

Ambient Temperature Effect (Controller)

Maximum output change, at midspan and 100% proportional band, for a 28° C (50° F) change from reference operating conditions is less than 1.0% of output span.

Supply Pressure Effect (Controller)

Maximum output change at midspan for a 115 to 155 kPa (17 to 22 psi, 1.15 to 1.55 bar or kg/cm2) supply pressure change is less than 1.2% of output span.

Position Effect (Controller)

Maximum output change, at midspan and 100% proportional band, for a 5° tilt in any direction from the upright position is less than 0.5% of output span.

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222

Supplied by DP-Flow