LIV Slimline Monoflange

LIV Slimline Monoflange Valves

Principle

LIV Slimline Monoflange Valve with isolating valve

Construction

The valve body is machined from a round bar stock material.

The raw material of the valve can be supplied according to NORSOK

M 630 or to customer ́s specific requirements.

Inlet is a flanged connection, outlet 1⁄2” NPT.

The valve spindle thread is external to stuffing box.

The valve has back-seating and non-rotating valve tip

The dust covers are coloured for application indication (isolate, equalize)

The valves are designed for PED 97/23EC.

Technical Data

| Material | AISI 316, A350LF2, 22Cr Duplex, 25Cr Duplex, 6Mo,AISI 316, A350LF2, 22Cr Duplex, 25Cr Duplex, 6Mo, Titanium, Monel 400, Hastelloy C, Inconel 625 and 825 |

| Size | DN 08 - DN 80, 1⁄4" - 3" |

| Pressure rating | 150 lbs – 2500 lbs |

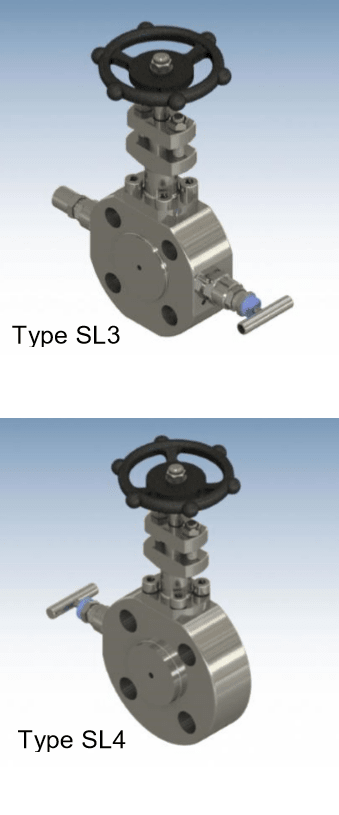

| Packing | PTFE, Graphite |

| Temperature | ÷50 to 400 oC depending on material |

| Operation | OS&Y, T-bar or Anti tamper |

| Valve Tip | Hardened |

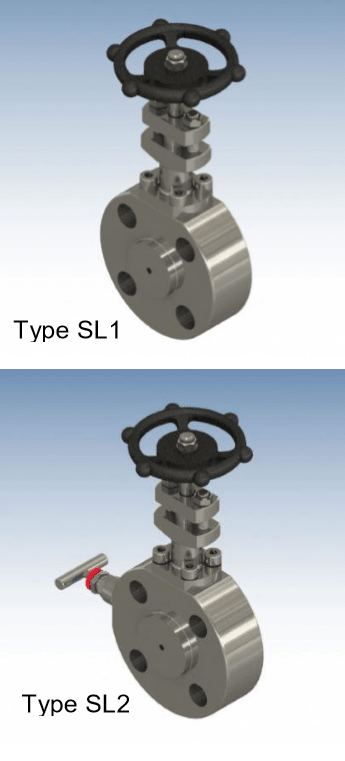

| Types | SL1, SL2, SL3, SL4 |

Testing and Documentation

Material certificate to EN 10204-3.1 and 3.2

Certificate of compliance to NACE MR 01-75 or EN 15156

Cleaned for Oxygen

Pressure test certificate

Fire safe tested

Accessories

1⁄4” NPT plugs (for valves with drain connection)

Valve coding

SL1 - single shut off, flanged inlet, threaded outlet

SL2 - block and bleed, flanged inlet, threaded outlet

SL3 - double block and bleed, flanged inlet, threaded outlet

SL4 - double block, flanged inlet, threaded outlet

Valve Size

| # | DN | ASME |

| 1 | 08 | 1⁄4” |

| 2 | 10 | 3/8" |

| 3 | 15 | 1/2" |

| 4 | 20 | 3/4" |

| 5 | 25 | 1" |

| 6 | 40 | 1 1⁄2” |

| 7 | 50 | 2" |

| 8 | 80 | 3" |

| 9 | Special |

Bonnet selction. Top, first shut off, middle second shut off, bottom vent

1 - OS&Y

2 - needle

3 - Anti Tamper

4 - needle, bolted

SL1 Combinations:

| 01 | 02 | 03 | 04 | 05 |

| 1 | 2 | 3 | 4 |

SL2, SL4 Combinations:

| 01 | 02 | 03 | 04 | 05 | 06 | 06 |

| 1 | 2 | 1 | 1 | 4 | ||

| 2 | 2 | 3 | 4 | 4 |

SL3 Combinations:

| 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 |

| 1 | 2 | 1 | 2 | 1 | |||||

| 2 | 2 | 1 | 2 | 2 | |||||

| 3 | 3 | 3 | 2 | 2 |

Pressure Rating

015 - 150lbs

030 - 300lbs

060 - 600lbs

150 - 1500lbs

250 - 2500lbs

Flance Facing

RF - raised face

RTJ ring type joint

| Material | Valve Body | Trim |

| 01 | A350 LF2 | 316 |

| 02 | A479 316 | 316 |

| 04 | A479 22Cr duplex | 22Cr duplex |

| 06 | A479 25Cr duplex | 25Cr duplex |

| 08 | A479 6Mo | 6Mo |

| 10 | Titanium | Titanium |

| 11 | Monel 400 | Monel 400 |

| 12 | Hastelloy C-276 | Hastelloy C-276 |

| 13 | Inconel 625 | Inconel 625 |

| 14 | Inconel 825 | Inconel 825 |

| 20 | Other, please specify |

Seals

T - PTFE solid

B - Teflon Checron V rings

C - PTFE, braided

G - Grafoil

Other - please specify

Vent connection

14 - 1/4" NPT int.

12 1/2" NPT int.

Connection outlet

1 - 1/2" NPT int.

2 - 3/4" NPT int.

3 - 1/2" NSPT int.

4 - 3⁄4” BSPT int.

5 - 1⁄2” SW

6 - 3⁄4” SW

7 - kidney flange

Surface treatment

P1 - standard off shore coating

P2 - customer specific coating: to be specified in clear language

P3 - none

Documentation

C1 - material certificate to EN 10204-3.1

C2 - certificate to NACE MR0175

C3 - certificate to ISO 15156

C4 - pressure test certificate

C5 - leak test certificate

C6 - PED certificate

D1 - dimensional drawing

I1 instruction manual

Customer's Standards

S - Please specify in plain words

Configuration

SL3-5-01-150-RTJ-04-GTT-12-1-C1D1

Slim line valve double block and bleed, OS&Y, needle, anti-T, valve size 1” 1500 lbs rating with RTJ facing, body in 22Cr. Duplex, packing in Grafoil/PTFE/PTFE, 1⁄2” bleed connection, 1⁄2” NPT int. outlet, material certificate and dimensional drawing.